在车辆制造、石油化工、海洋工程等行业中,机械设备零部件常遭受磨损和腐蚀的侵袭,进而显著缩短了其使用寿命。为有效延长这些零部件的服役期限,表面改性技术,特别是超高速激光熔覆技术,成为一种有效的解决方案。相比于传统的涂层技术,超高速激光熔覆凭借其高效的熔覆速率和优良的熔覆质量,能够避免过高的热输入对基体材料造成的损伤,受到了众多研究者的广泛关注。该技术能够在较低的热输入条件下,确保涂层与基体之间形成良好的冶金结合,同时促进微观结构的细化和成分的均匀分布。其工艺参数,如激光功率、扫描速度、送粉率和搭接率,对涂层的质量和性能具有重要影响。不同的涂层材料,包括合金粉末、高熵合金粉末、非晶粉末和复合粉末,依据具体应用需求及基体材料的特性进行选择。涂层缺陷,如气孔和裂纹,常与工艺参数的选择和熔覆层与基体之间的热膨胀系数差异有关。从工艺参数优化、材料体系选择和缺陷类型分析等多个维度,系统阐述超高速激光熔覆技术的最新研究进展,总结了各种涂层材料的主要特点,探讨工艺参数对涂层性能的影响和分析涂层缺陷的形成机理。

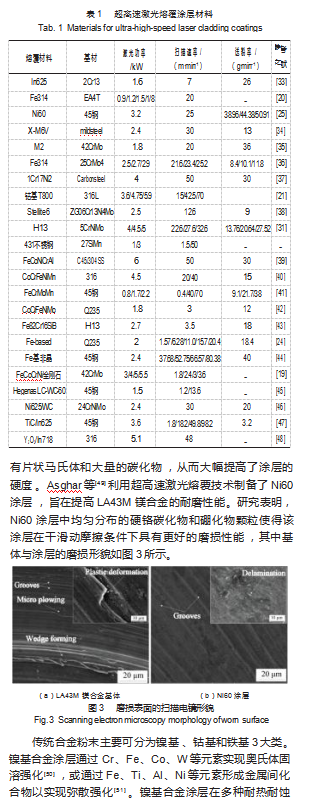

钢铁材料因其制造成本低廉、机械性能优异以及良好的可加工性等优点,在车辆制造、电力行业、船舶工程及海洋工程等多个工业领域的机械设备零部件中得到了广泛应用[1]。然而,机械设备零部件在极端或恶劣的工作环境中,常面临磨料磨损、腐蚀磨损及疲劳磨损等多重失效机制的共同作用。这些失效机制相互交织,共同作用于机械设备零部件的表面,加速了其损耗过程,进而缩短了设备的使用寿命。随着经济的持续发展和工业技术水平的不断提高,对机械设备的质量和使用寿命提出了更为严格的要求。因此,通过优化材料的表面性能,显著提升零部件的耐磨性和耐腐蚀性而有效延长设备的使用寿命,已成为一项至关重要的任务。

为提高钢表面的耐磨性和耐腐蚀性能,通常采用表面改性技术在钢表面制备薄膜、涂层或渗层,以实现服役性能的优化。钢表面常用的表面改性技术包括气相沉积[2-3]、热喷涂[4]、化学热处理[5-6]等。气相沉积又可细分为物理气相沉积和化学气相沉积。物理气相沉积形成的薄膜均匀且与基体结合力强,薄膜的物理性能优异;化学气相沉积则易于控制薄膜的成分和特性,能够灵活应对复杂形状零件的加工需求,展现出高度的工艺灵活性与适应性。热喷涂技术适应性强,能在各种基体材料上进行喷涂,且可喷涂的涂层材料种类极为广泛。其中,等离子喷涂[7]、火焰喷涂[8]、超音速火焰喷涂[9]等作为热喷涂技术的典型代表,不仅提高了涂层的致密性与结合强度,还显著增强了涂层的耐磨性、耐蚀性能,能够满足不同工程领域的特定需求。化学热处理技术,以其低成本、高效率和显著的性能提升效果,成为增强钢材表面硬度和耐腐蚀性的又一重要途径。该技术通过控制元素在钢表面的扩散与反应,实现表面层的改性,具体方法包括渗氮[10]、渗碳[11]和碳氮共渗[12]。

气相沉积、热喷涂、化学热处理等传统表面改性技术在过往的生产实践中均取得了良好的应用成效。然而,随着制造业向高端化、绿色化转型的加速,以及环保法规体系的不断完善,这些传统技术所固有的局限性开始愈发凸显。化学热处理技术面临生产周期长、能耗较高的难题;热喷涂技术虽应用广泛,但涂层与基材间的结合强度较低;而气相沉积技术,尤其是化学气相沉积,虽能制备出高质量涂层,却难以避免化学污染及生产成本偏高的问题。在此背景下,激光表面改性技术作为一种新型表面处理手段,正在金属材料的改性领域中逐渐崭露头角。该技术凭借其非接触式加工、精确控制、高效能、低污染的特性,以及能够显著提升材料表面硬度、耐磨性、耐腐蚀性等综合性能的优势,已成为满足现代工业对高质量、高效率、低环境影响产品需求的关键技术之一。

激光因其能量密度高,相干性和方向性优良等特性,在材料表面处理技术领域展现出了广阔的应用前景。激光表面改性技术主要包括激光表面合金化[13]、激光熔覆[14]、激光重熔[15]等。激光熔覆技术作为一种即时高效的加工手段,通过激光束直接照射涂层粉末,促使粉末迅速熔化并快速固化于基体表面,形成一层致密且性能优异的涂层。熔覆过程中,涂层经历极大的温度梯度,促进了细小晶粒的形成,并与基体之间形成良好的冶金结合[16],从而显著提升了涂层的机械性能及与基体之间的附着力。与其他表面改性技术相比,激光熔覆技术具有生产效率高、涂层与基材结合力强、熔覆层组织致密、且环境友好等特点[17]。德国弗劳恩霍夫激光技术研究所(Fraunhofer ILT)与亚琛工业大学(RWTH Aachen)于2017年联合开发了超高速激光熔覆技术(Extreme High-Speed Laser Material Deposition,EHLA)[18],在传统激光熔覆技术的基础上,通过优化熔覆头结构,实现了粉末在到达基材前的预熔化,使粉末以液态形式在基材表面凝固,形成均匀涂层。与传统激光熔覆相比,超高速激光熔覆显著提高了能量利用效率,粉末利用率可达85%,稀释率低于5%。该技术有效缩小了热影响区(HAZ),大幅减少了基材热变形的发生,同时降低了涂层稀释率,避免了成分偏析。使用较小粒径的粉末和较高的搭接率,使涂层成形质量更高,组织更致密。此外,超高速激光熔覆的熔覆速度高达25~200 m/min,是传统激光熔覆速度的数倍。超高速激光熔覆提高了涂层材料沉积速率,突破了传统激光熔覆技术的效率瓶颈。高熔覆速率不仅提升了涂层的冷却速率,还显著减少了基材熔池的形成与持续时间。所得到的涂层更加致密和均匀,减少了气孔和裂纹的形成,提高了涂层的性能。

本文系统性地阐述了超高速激光熔覆技术中关键工艺参数的特性及其所涉及的材料体系。综述了这些关键工艺参数对涂层熔覆效果的影响,并概述了不同涂层材料体系所展现的独特性质。简要概括了超高速激光熔覆的典型应用场景,提出了今后涂层评价体系的发展方向。

激光功率是影响基体热输入的关键因素之一。在一定的范围内增加激光功率,可以为粉末的熔化及固结过程提供更为充足的能量,并相应地延长激光束与粉末颗粒的相互作用时间,从而有助于提高粉末的利用率。然而,当激光功率过高时会导致粉末发生高温气化现象,使得涂层稀释率上升,导致涂层质量的显著降低。

Wang等[19]在42CrMo钢基体上制备了FeCoCrNiMo/金刚石复合涂层,并观察到随着激光功率的提升,金刚石的碳化程度显著增加。在高温环境下,金刚石碳化导致更多碳原子向涂层内部扩散,并与空气中的氧气反应生成气体产物。另一方面,由于高冷却速率的作用,熔融粉末迅速凝固形成涂层,致使部分气体无法逸出而残留于涂层中,从而在一定程度上增加了涂层的孔隙率。过高的激光功率不仅会导致涂层质量下降,还会加剧粉末材料的溶解,进而对涂层的厚度产生不利影响。Zhang等[20]利用高速摄像机捕捉送粉过程,系统研究了不同激光熔覆功率、载气流量以及送粉率条件下熔覆过程的动态行为。实验结果显示,在900~1 800 W的激光功率范围内,随着激光功率的增加,熔融粉末量逐渐增大,导致涂层厚度相应增加。然而,当激光功率达到1 800 W时,粉末气化现象加剧,导致粉末损失严重。Yong等[21]在探究激光功率对涂层厚度影响的研究中,随着激光功率的增大(3.6、4.75、5.9 kW),被捕获的粉末量增多,导致涂层厚度略有增加,这一过程中涂层硬度有所下降(最大值1 580、1 380、1 000 HV0.1),其原因可能是涂层中碳化物相的粘结程度降低。

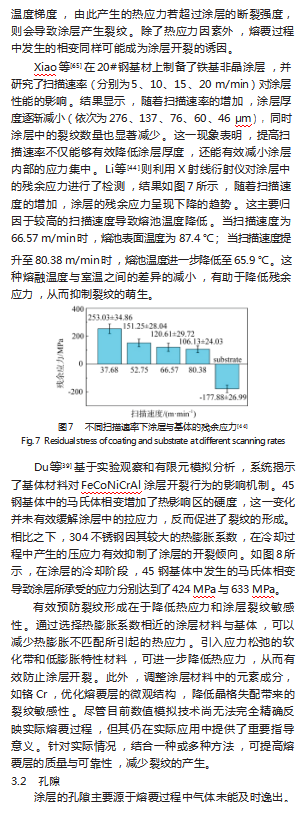

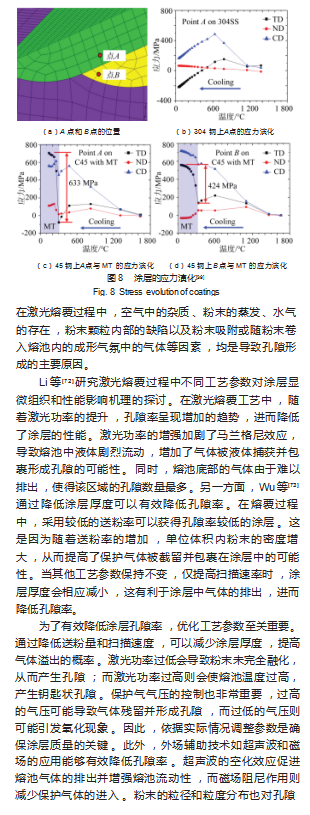

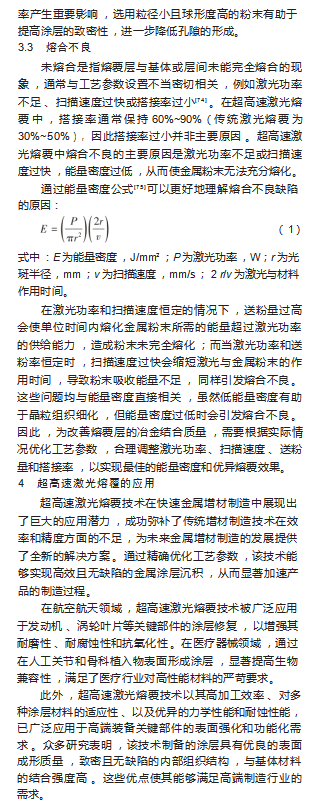

扫描速率对涂层性能具有显著影响。在一定范围内调整扫描速率,会直接影响对基体的热输入量,进而提高涂层的冷却速率,促使涂层微观组织的细化,并最终增强涂层的摩擦磨损及耐腐蚀性能。

Yuan等[22]研究了传统激光熔覆与超高速激光熔覆之间的差异。超高速激光熔覆由于具有较高的扫描速率,能够显著提升涂层的冷却速率,促使粗大柱状晶向细小的枝晶转变,进而提高了涂层的摩擦磨损性能。Chen等[23]在45钢上熔覆了TiC/In625涂层,并深入研究了涂层的表面形貌和微观组织结构,发现随着扫描速率的增加,涂层表面粗糙度呈现降低的趋势。与传统激光熔覆相比,高熔覆速率使得枝晶尺寸进一步减小,同时基体受热输入的影响也相对较小。此外,涂层的稀释率较低,成分分布更为均匀。Jian等[24]研究了扫描速率(1.57~20.4 m/min)对涂层耐腐蚀性能的影响。随着扫描速率的提高,涂层的微观组织发生了显著的细化。扫描速率的提高促使Cr元素在枝晶之间实现了更为均匀的分布,这有助于减小电位差,从而提高了涂层的耐腐蚀性能。

送粉率主要对涂层厚度产生影响。送粉率的设定需与适宜的激光功率及扫描速率相配合。若激光功率过低或扫描速率过快,均可能导致粉末熔化不完全,从而难以与基体形成良好的冶金结合。此外,这种不完全熔化还会导致涂层表面残留未熔粉末,进而增大涂层表面粗糙度。

Meng等[25]在45钢基材上沉积了Ni60涂层,研究了不同工艺参数对Ni60涂层微观组织的影响。随着送粉率的增加(38.96、44.38、50.91 g/min),涂层的厚度与粗糙度亦呈现上升趋势。此外,送粉率还显著影响熔覆效率,为了平衡熔覆效率与涂层质量,调整送粉率的同时,其他相关工艺参数亦需进行相应优化。Someer等[26]则聚焦于超高速激光熔覆工艺参数对涂层厚度的影响,采用了两种不同粒径的粉末,并设计了关于激光功率与送粉率的全因子实验。实验结果如图1所示,该涂层厚度的等高线明显平行于激光功率轴,而垂直于送粉率轴,表明送粉率是决定涂层厚度的主导因素。Schaible等[27]则针对送粉率对粉末利用率的影响展开了研究。在送粉率达到最大值70.9 g/min且激光功率为5 kW的条件下,已无法确保涂层和基体之间形成良好的冶金结合,涂层厚度增大的同时,涂层孔隙增加,涂层质量下降。涂层质量与粉末粒径、粉末球形度也存在一定的关联性。不同粒径的粉末对激光吸收能力不同,在激光熔覆过程中会导致熔池形状和尺寸的变化,进而影响涂层成形形貌[28]。当粉末粒径增大到一定程度,激光能量不足以使粉末完全融化,导致粉末团聚现象加剧,从而影响其表面粗糙度和尺寸精度[29]。另外,相同粒径但球形度更高的粉末,具有更好的流动性和松装密度,能够提高熔覆层的厚度均匀性和组织致密度。马宽等[30]研究粉末球形度对熔覆质量的影响,发现SS-PREP粉熔覆层厚度变化波动较GA粉熔覆层小;SS-PREP粉熔覆层厚度平均值为10.98μm;GA粉熔覆层厚度平均值为54.53μm。SS-PREP粉较GA粉,熔覆层内部微观组织表现为更细小的等轴树枝晶。

搭接率对涂层粗糙度具有显著影响。在超高速激光熔覆工艺中,搭接率通常维持在50%~90%的范围内。当搭接率偏低时,会导致涂层堆积密度不足,进而造成涂层表面质量下降。值得注意的是,高搭接率并不必然等同于优异的表面质量。因此,确定搭接率的具体数值时,需综合考虑生产过程的实际需求、设备性能以及其他相关因素。

Yan等[31]利用超高速激光熔覆技术在5CrNiMo基材上成功制备了H13钢涂层,并采用响应曲面法优化了涂层的厚度与粗糙度。在搭接率30%~90%的范围内,搭接率与涂层厚度呈现正相关关系。关于搭接率对涂层厚度的影响,Lampa等[32]在20MnV6基材上制备了In625涂层,在扫描速率恒定为100 m/min的条件下,拟合出了涂层厚度随送粉率、激光功率和搭接率变化的曲线,如图2所示。随着搭接率的增加,涂层厚度也相应地增加。

在模具修复领域,激光熔覆技术通过将合金材料精确沉积在模具表面,大幅提升了模具的耐久性和性能,特别适用于金属加工和制造过程中的关键环节。然而,目前超高速激光熔覆设备主要应用于轧辊、柱塞和液压支架等旋转对称零件,其对自由曲面和大型平面部件的加工能力仍存在一定限制,这在一定程度上限制了其应用范围的进一步扩展。

5结束语

本文通过工艺参数、材料体系和缺陷分析等3个维度,全面阐述了超高速激光熔覆技术的研究现状。超高速激光熔覆技术在传统激光熔覆的基础上,对熔覆头的结构进行了优化,显著提升了扫描速率,进而提高了熔覆效率,降低了涂层稀释率,并实现了晶粒的细化,使得涂层成分均匀分布,进一步提高了涂层的质量。工艺参数对涂层质量具有至关重要的影响。激光功率能够影响粉末的熔化程度和熔覆效率。关于扫描速率的研究较为丰富,这些研究主要聚焦于细晶强化对涂层性能的提升作用。送粉率是影响涂层厚度的重要因素之一,综合考虑送粉率与激光功率之间的相互作用,有助于实现涂层与基体的良好结合。此外,搭接率主要影响涂层的表面粗糙度,同时也是影响涂层厚度的一个因素。在选择熔覆材料时,需根据基材的特点与材料表面性能的要求,选取合适的熔覆材料,以提高零件表面的耐磨性、耐腐蚀性、耐高温及抗氧化性能。合金粉末通过相变和第二相强化机制来提高涂层的性能。而高熵合金粉末和非晶粉末因其特殊的相结构而展现出优异的性能,有望在未来的生产实践中得到广泛应用。金属复合粉末则通过引入陶瓷相,进一步提升了涂层的综合性能。

超高速激光熔覆技术在金属增材制造领域展现出显著优势,弥补了传统增材制造在效率和精度上的不足。通过优化工艺参数,该技术能够快速沉积高质量、无缺陷的金属涂层,实现质量减轻与性能提升的双重目标。该技术已在航空航天、医疗器械和高端装备制造等领域得到应用。其对非旋转对称零件的加工能力有限,仍需进一步优化设备与工艺,以扩大应用范围并更好满足绿色制造和高端加工的需求。

众多研究将摩擦磨损与电化学腐蚀作为涂层性能评价的指标。为更全面地反映实际服役环境的复杂性,未来的研究需引入更多元化的评价标准,如空泡腐蚀、冲刷腐蚀以及腐蚀摩擦磨损等综合性能评价,以提高涂层质量评价的准确性和全面性。同时,熔合不良、孔隙与裂纹是影响涂层质量的主要缺陷。熔合不良通常由激光功率不足、扫描速度过快或送粉量过高等因素导致,表现为熔覆层与基体或层间未完全熔合。孔隙则由粉末气化或熔池凝固不均匀引起,裂纹则通常与热应力集中和材料的脆性有关。这些缺陷不仅影响涂层的冶金结合质量,还可能降低其机械性能和服役寿命。为有效控制这些缺陷,可通过构建孔隙与裂纹的三维模型,结合能量密度优化,深入分析工艺参数对涂层质量的影响。通过系统的缺陷分析与质量优化方法,可为提升涂层的整体性能提供有力支持,进而推动超高速激光熔覆技术在更多领域的应用。

参考文献:

[1]Maya J,Sivaprasad K,Sarath Kumar G V,et al.Microstructure,Mechanical properties,and corrosion behavior of 06Cr15Ni4Cu⁃Mo processed by using selective laser melting[J].Metals,2022,12(8):1303.

[2]Takadoum J,Houmid Bennani H,Mairey D,et al.Adhesion and wear resistance of thin hard coatings[J].Journal of the European Ceramic Society,1997,17(15-16):1929-1932.

[3]Gowri M,Van Enckevort W J P,Schermer J J,et al.Growth and adhesion of hot filament chemical vapor deposited diamond coat⁃ings on surface modified high speed steel[J].Diamond and Relat⁃ed Materials,2009,18(12):1450-1458.

[4]Zhao L,Lugscheider E,Fischer A,et al.Thermal spraying of a high nitrogen duplex austenitic-ferritic steel[J].Surface and Coatings Technology,2001,141(2-3):208-215.

[5]Sun Y,Bailey R.Comparison of Wear Performance of Low Tem⁃perature Nitrided and Carburized 316L Stainless Steel under Dry Sliding and Corrosive-Wear Conditions[J].Journal of Materials Engineering and Performance,2023,32(3):1238-1247.

[6]Cai W,Meng F,Gao X,et al.Effect of QPQ nitriding time on wear and corrosion behavior of 45 carbon steel[J].Applied Sur⁃face Science,2012,261:411-414.

[7]杨均,姚青,李怀峰,等.等离子喷涂硅酸盐搪瓷涂层及其热循环行为研究[J].电镀与涂饰,2024,43(2):76-83. YANG J,YAO Q,LI H F,et al.Preparation of silicate enamel coating by plasma spraying and study on its thermal cycling be⁃havior[J].Electroplating&Finishing,2024,43(2):76-83.

[8]沈明禄,赵连红,何卫平,等.起落架用高速火焰喷涂WC涂层覆盖高强钢海水环境腐蚀与开裂行为[J].材料工程,2024,52(2):207-217.SHEN M L,ZHAO L H,HE W P,et al.Corrosion and cracking behavior of high strength steel covered with high-velocity oxy⁃gen-fuel spraying WC coating in marine environment[J].Journal of Materials Engineering,2024,52(2):207-217.

[9]刘思思,杨正航,武云文,等.超音速火焰喷涂Ni-CeO2复合涂层的数值模拟及耐磨耐腐蚀性能[J].中国表面工程,2023,36(3):180-192.LIU S S,YANG Z H,WU Y W,et al.Numerical simulation and abrasion and corrosion resistance properties of hvof Ni-CeO_2 composite coatings[J].China Surface Engineering,2023,36(3):180-192.

[10]龙有红,任岩平,何添,等.31CrMoV9钢离子渗氮层的微动摩擦磨损特性研究[J].摩擦学学报,2024,44(5):633-643.LONG Y H,REN Y P,HE T,et al.Study on fretting wear behav⁃iour of plasma nitriding layer of 31CrMoV9 steel[J].Tribology,2024,44(5):633-643.

[11]Ismail M A,Anwar M,Singh J K,et al.Carburization-induced surface modification of Ti-6Al-7Nb alloy and its characteriza⁃tion[J].Journal of Alloys and Compounds,2024,1002:175436.

[12]Chen R,Chen H,Ye C,et al.Friction,wear,and corrosion be⁃havior of nitrocarburized HT250 gray cast iron[J].International Journal of Electrochemical Science,2024,19(6):100582.

[13]Nair A M,Muvvala G,Nath A K.A study on in-situ synthesis of TiCN metal matrix composite coating on Ti–6Al–4V by laser surface alloying process[J].Journal of Alloys and Compounds,2019,810:151901.

[14]Deng D,Li T,Huang Z,et al.Multi-response optimization of la⁃ser cladding for TiC particle reinforced Fe matrix composite based on Taguchi method and grey relational analysis[J].Optics&Laser Technology,2022,153:108259.

[15]Zhang D,Qin Y,Feng W,et al.Microstructural evolution of the amorphous layers on Mg-Zn-Ca alloy during laser remelting process[J].Surface and Coatings Technology,2019,363:87-94.

[16]Zhou S,Dai X,Zeng X.Effects of processing parameters on structure of Ni-based WC composite coatings during laser in⁃duction hybrid rapid cladding[J].Applied Surface Science,2009,255(20):8494-8500.

[17]Zhu L,Xue P,Lan Q,et al.Recent research and development status of laser cladding:A review[J].Optics&Laser Technolo⁃gy,2021,138:106915.

[18]Raykis O.Alternative with a Future:High⁃speed laser metal de⁃position replaces hard chrome plating[J].Laser Technik Journal,2017,14(1):28-30.

[19]Wang H,Zhang W,Peng Y,et al.Microstructures and Wear Re⁃sistance of FeCoCrNi-Mo High Entropy Alloy/Diamond Com⁃posite Coatings by High Speed Laser Cladding[J].Coatings,2020,10(3):300.

[20]Zhang W,Liu Y,Hu D,et al.Experimental and numerical simu⁃lation studies of the flow characteristics and temperature field of Fe-based powders in extreme high-speed laser cladding[J].Op⁃tics&Laser Technology,2024,170:110317.

[21]Yong Z,Chang L,Jiang S,et al.Parameter optimization of T800 coating fabricated by EHLA based on response surface method⁃ology[J].Optics&Laser Technology,2023,158:108837.

[22]Yuan W,Li R,Chen Z,et al.A comparative study on micro⁃structure and properties of traditional laser cladding and high-speed laser cladding of Ni45 alloy coatings[J].Surface and Coat⁃ings Technology,2021,405:126582.

[23]Chen L,Zhang X,Wu Y,et al.Effect of surface morphology and microstructure on the hot corrosion behavior of TiC/IN625 coat⁃ings prepared by extreme high-speed laser cladding[J].Corro⁃sion Science,2022,201:110271.

[24]Jian Y,Liu Y,Qi H,et al.Effects of scanning speed on the mi⁃crostructure,hardness and corrosion properties of high-speed laser cladding Fe-based stainless coatings[J].Journal of Materi⁃als Research and Technology,2024,29:3380-3392.

[25]Meng L,Sheng P,Zeng X.Comparative studies on the Ni60 coatings deposited by conventional and induction heating assist⁃ed extreme-high-speed laser cladding technology:formability,microstructure and hardness[J].Journal of Materials Research and Technology,2022,16:1732-1746.

[26]Sommer N,Stredak F,Böhm S.High-Speed Laser Cladding on Thin-Sheet-Substrates—Influence of Process Parameters on Clad Geometry and Dilution[J].Coatings,2021,11(8):952.

[27]Schaible J,Sayk L,Schopphoven T,et al.Development of a high-speed laser material deposition process for additive manu⁃facturing[J].Journal of Laser Applications,2021,33(1):012021.

[28]岳琨,练国富,陈昌荣,等.激光熔覆粉末粒径对熔覆层成形控制的影响[J].精密成形工程,2022,14(3):58-67.YUE K,LIAN G F,CHEN C R,et al.Effect of powder particle size of laser cladding on the forming control of cladding layer[J].Journal of Netshape Forming Engineering,2022,14(3):58-67.

[29]Kouprianoff D,Yadroitsava I,Du Plessis A,et al.Monitoring of Laser Powder Bed Fusion by Acoustic Emission:Investigation of Single Tracks and Layers[J].Frontiers in Mechanical Engi⁃neering,2021,7:678076.

[30]马宽,唐洪奎,卓君,等.粉末球形度对高速激光熔覆层质量的影响[J].铸造,2022,71(5):586-591.MA K,TANG H K,ZHUO J,et al.Effect of powder sphericity on quality of coatings prepared by highspeed laser cladding[J].Foundry,2022,71(5):586-591.

[31]Yan Q,Yang K,Wang Z,et al.Surface roughness optimization and high-temperature wear performance of H13 coating fabri⁃cated by extreme high-speed laser cladding[J].Optics&Laser Technology,2022,149:107823.

[32]Lampa C,Smirnov I.High speed laser cladding of an iron based alloy developed for hard chrome replacement[J].Journal of La⁃ser Applications,2019,31(2):022511.

[33]Liu M X,Li Z,Chang G R,et al.An Investigation of the Surface Quality and Corrosion Resistance of Laser Remelted and Ex⁃treme High-Speed Laser Cladded Ni-based Alloy Coating[J].International Journal of Electrochemical Science,2022,17(5):220537.

[34]Ren Y,Li L,Zhou Y,et al.In situ synthesized VC reinforced Fe-based coating by using extreme high-speed laser cladding[J].Materials Letters,2022,315:131962.

[35]Zhang N,Xu Y fei,Wang M hui,et al.M2 coating prepared by ultra-high speed laser cladding:Microstructure and interfacial residual stress[J].Materials Today Communications,2023,35:105638.

[36]Lv H,Liu Y,Chen H,et al.Temperature field simulation and microstructure evolution of Fe-based coating processed by ex⁃treme high-speed laser cladding for re-manufacturing locomo⁃tive axle[J].Surface and Coatings Technology,2023,464:129529.

[37]Ding Y,Du C,Wang X,et al.Microstructure and interfacial metallurgical bonding of 1Cr17Ni2/carbon steel extreme high-speed laser cladding coating[J].Advanced Composites and Hy⁃brid Materials,2021,4(1):205-211.

[38]张林,刘刚,曾东,等.超高速激光熔覆Stellite 6涂层的抗汽蚀及冲蚀性能[J].表面技术,2022,51(4):167-175.ZHANG L,LIU G,ZENG D,et al.Anti-cavitation and erosion resistance of stellite 6 coating by ultra-high speed laser clad⁃ding[J].Surface Technology,2022,51(4):167-175.

[39]Du C,Hu L,Ren X,et al.Cracking mechanism of brittle Fe⁃CoNiCrAl HEA coating using extreme high-speed laser clad⁃ding[J].Surface and Coatings Technology,2021,424:127617.

[40]Du J L,Xu X,Zhang H M,et al.Microstructure and wear resis⁃tance of CoCrFeNiMn coatings prepared by extreme-high-speed laser cladding[J].Surface and Coatings Technology,2023,470:129821.

[41]Yang J,Bai B,Ke H,et al.Effect of metallurgical behavior on microstructure and properties of FeCrMoMn coatings prepared by high-speed laser cladding[J].Optics&Laser Technology,2021,144:107431.

[42]Zhang Q,Li M,Wang Q,et al.Investigation of the Microstruc⁃ture and Properties of CoCrFeNiMo High-Entropy Alloy Coat⁃ing Prepared through High-Speed Laser Cladding[J].Coatings,2023,13(7):1211.

[43]Liu M,Jiang H,Chang G,et al.Effect of laser remelting on cor⁃rosion and wear resistance of Fe82Cr16SiB alloy coatings fabri⁃cated by extreme high-speed laser cladding[J].Materials Let⁃ters,2022,325:132823.

[44]Li R,Yuan W,Yue H,et al.Study on microstructure and prop⁃erties of Fe-based amorphous composite coating by high-speed laser cladding[J].Optics&Laser Technology,2022,146:107574.

[45]张煜,娄丽艳,徐庆龙,等.超高速激光熔覆镍基WC涂层的显微结构与耐磨性能[J].金属学报,2020,56(11):1530-1540.ZHANG Y,LOU L Y,XU Q L,et al.Microstructure and wear re⁃sistance of ni-based wc coating by ultra-high speed laser clad⁃ding[J].ACTA METALLURGICA SINICA,2020,56(11):1530-1540.

[46]李宝程,崔洪芝,宋晓杰,等.超高速激光熔覆Ni625/WC复合涂层的耐磨性能[J].表面技术,2023,52(11):237-247. LI B C,CUI H Z,SONG X J,et al.Wear resistance of ultra-high speed laser cladding ni625/wc composite coatings[J].Sur⁃face Technology,2023,52(11):237-247.

[47]Ge T,Chen L,Gu P,et al.Microstructure and corrosion resis⁃tance of TiC/Inconel 625 composite coatings by extreme high speed laser cladding[J].Optics&Laser Technology,2022,150:107919.

[48]Lin F,Wang Z,Xu X,et al.The effect of Y2O3 nanoparticle ad⁃dition on the microstructure and high-temperature corrosion re⁃sistance of IN718 deposited by extreme high-speed laser clad⁃ding[J].Surface and Coatings Technology,2024,476:130235.

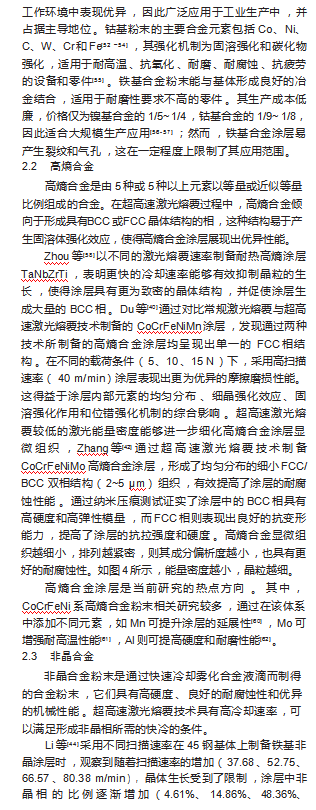

[49]Asghar O,LI Y L,Yasir M,et al.Enhanced Tribological Proper⁃ties of LA43M Magnesium Alloy by Ni60 Coating via Ultra-High-Speed Laser Cladding[J].Coatings,2020,10(7):638.

[50]Li X,Zhu W,Shen H,et al.Microstructures and high-tempera⁃ture oxidation behavior of laser cladded NiCoCrAlYSi coating on Inconel 625 Ni-based superalloy modified via high current pulsed Electron beam[J].Surface and Coatings Technology,2021,427:127796.

[51]Liu K,Li Y,Wang J.In-situ reactive fabrication and effect of phosphorus on microstructure evolution of Ni/Ni-Al intermetal⁃lic composite coating by laser cladding[J].Materials&Design,2016,105:171-178.

[52]Han J,Yoo B,Im H J,et al.Microstructural evolution of the heat affected zone of a Co-Ti-W alloy upon laser cladding with a CoNiCrAlY coating[J].Materials Characterization,2019,158:109998.

[53]Qin R,Zhang X,Guo S,et al.Laser cladding of high Co-Ni sec⁃ondary hardening steel on 18Cr2Ni4WA steel[J].Surface and Coatings Technology,2016,285:242-248.

[54]Niederhauser S,Karlsson B.Fatigue behaviour of Co-Cr laser cladded steel plates for railway applications[J].Wear,2005,258(7-8):1156-1164.

[55]Zhao J,Gao Q,Wang H,et al.Microstructure and mechanical properties of Co-based alloy coatings fabricated by laser clad⁃ding and plasma arc spray welding[J].Journal of Alloys and Compounds,2019,785:846-854.

[56]Wei A,Tang Y,Tong T,et al.Effect of WC on Microstructure and Wear Resistance of Fe-Based Coating Fabricated by Laser Cladding[J].Coatings,2022,12(8):1209.

[57]Zhu L N,Xu B S,Wang H D,et al.Microstructure and nanoin⁃dentation measurement of residual stress in Fe-based coating by laser cladding[J].Journal of Materials Science,2012,47(5):2122-2126.

[58]Zhou J L,Cheng Y H,Wan Y X,et al.Solidification characteris⁃tics and microstructure of TaNbZrTi refractory high entropy coating by extreme high-speed laser cladding[J].International Journal of Refractory Metals and Hard Materials,2023,115:106257.

[59]王一丹,张学润,崔秀芳,等.激光能量密度对NiCrCoTiV高熵合金涂层组织结构及耐蚀性能的影响[J].表面技术,2019,48(6):118-124. WANG Y D,ZHANG X R,CUI X F,et al.Effects of laserener⁃gy density on microstructure and corrosion resistance of nicrcotiv high entropy alloy coating[J].Surface Technology,2019,48(6):118-124.

[60]牛利冲,李杰,赵思杰,等.FeCoNiCrMn系高熵合金变形机制的研究进展[J].中国有色金属学报,2022,32(8):2316-2326.NIU L C,LI J,ZHAO S J,et al.Research progress of deforma⁃tion mechanism of femncocrni high entropy alloy system[J].The Chinese Journal of Nonferrous Metals,2022,32(8):2316-2326.

[61]赵海朝,梁秀兵,乔玉林,等.激光熔覆高熵合金涂层的研究进展[J].材料工程,2019,47(10):33-43.ZHAO H C,LIANG X B,QIAO Y L,et al.Research progress in high-entropy alloy coatings by laser cladding[J].Journal of Ma⁃terials Engineering,2019,47(10):33-43.

[62]冯英豪,李晓峰,刘斌,等.SiC颗粒对AlCoCrFeNi高熵合金涂层显微组织与力学性能的影响[J].热加工工艺,2019,48(8):160-163. FENG Y H,LI X F,LIU B,et al.Effects of sic particles on micro⁃structure and mechanical properties of alcocrfeni high-entropy alloy coating[J].Hot Working Technology,2019,48(8):160-163.

[63]Li R,Jin Y,Li Z,et al.Effect of the remelting scanning speed on the amorphous forming ability of Ni-based alloy using laser cladding plus a laser remelting process[J].Surface and Coatings Technology,2014,259:725-731.

[64]Zhu Y,Li Z,Huang J,et al.Amorphous structure evolution of high power diode laser cladded Fe-Co-B-Si-Nb coatings[J].Applied Surface Science,2012,261:896-901.

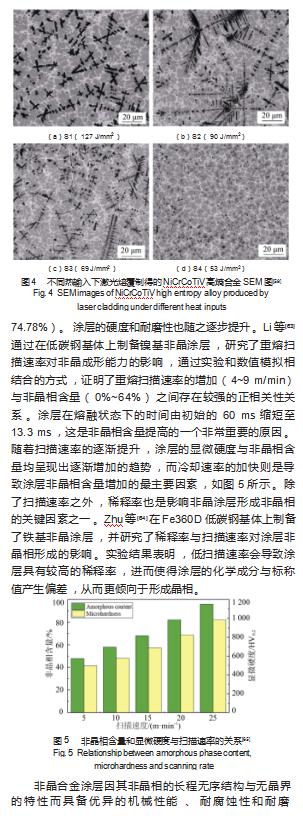

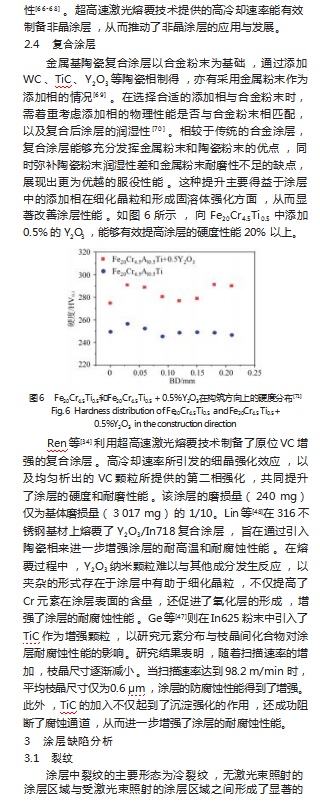

[65]Xiao M,Gao H,Sun L,et al.Microstructure and mechanical properties of Fe-based amorphous alloy coatings prepared by ul⁃tra-high speed laser cladding[J].Materials Letters,2021,297:130002.

[66]Shi L,Yao K.Composition design for Fe-based soft magnetic amorphous and nanocrystalline alloys with high Fe content[J].Materials and Design,2020,189:108511

[67]Lee C Y,Lin T J,Sheu H H,et al.A study on corrosion and cor⁃rosion-wear behavior of Fe-based amorphous alloy coating pre⁃pared by high velocity oxygen fuel method[J].Journal of Materi⁃als Research and Technology,2021,15:4880-4895.

[68]Xu J jie,Kang J jie,Yue W,et al.High-temperature tribologi⁃cal property of Fe-based amorphous alloy coating[J].Journal of Non-Crystalline Solids,2021,573:121136.

[69]王权,刘秀波,刘庆帅,等.45#钢激光熔覆Ni60/Cu自润滑复合涂层组织演变及摩擦学性能[J].中国表面工程,2022,35(6):232-243.WANG Q,LIU X B,LIU Q S,et al.Microstructure evolution and tribological properties of laser cladding Ni60/Cu self-lubri⁃cating composite coatings on 45#steel[J].China Surface Engi⁃neering,2022,35(6):232-243.

[70]Han T,Zhou K,Chen Z,et al.Research Progress on Laser Clad⁃ding Alloying and Composite Processing of Steel Materials[J].Metals,2022,12(12):2055.

[71]Wilms M B,Pirch N,Gökce B.Manufacturing oxide-disper⁃sion-strengthened steels using the advanced directed energy de⁃position process of high-speed laser cladding[J].Progress in Ad⁃ditive Manufacturing,2023,8(2):159-167.

[72]Li C,Zhai J,Tian L,et al.Fabrication of Fe-based amorphous composite coating by laser cladding[J].Journal of Non-Crystal⁃line Solids,2022,589:121648.

[73]Wu Z,Li T,Li Q,et al.Process optimization of laser cladding Ni60A alloy coating in remanufacturing[J].Optics&Laser Technology,2019,120:105718.

[74]张凤英,陈静,谭华,等.钛合金激光快速成形过程中缺陷形成机理研究[J].稀有金属材料与工程,2007(2):211-215.ZHANG F Y,CHEN J,TAN H,et al.Research on forming mech⁃anism of defects in laser rapid formed titanium alloy[J].RARE METAL MATERIALS AND ENGINEERING,2007(2):211-215.[75]Man H C,Zhang S,Cheng F T,et al.In situ synthesis of TiC re⁃inforced surface MMC on Al6061 by laser surface alloying[J].Scripta Materialia,2002,46(3):229-234.